Wearable IoT devices — from fitness bands and health monitors to smart glasses — are redefining how we interact with technology. Yet, one challenge continues to slow their adoption: battery life. Users expect always-on performance, but limited battery capacity often leads to frequent recharging, reduced usability, and lower satisfaction.

To address this, developers need systematic approaches to wearable battery optimization and IoT power saving, rooted in hardware design, firmware logic, radio communication tuning, and power management strategies. This article explores practical, research-backed techniques that extend battery life while maintaining device performance and user experience.

Why Battery Optimization Matters in Wearable IoT Design

Battery life isn’t just a technical metric — it’s a user expectation and market differentiator. Devices with poor battery performance face higher churn, negative reviews, and increased operational costs.

The User Experience Factor

Wearables such as health trackers and safety monitors require reliable uptime. A device that runs out of power during critical moments undermines user trust and brand credibility. Research shows that battery life ranks among the top decision criteria for wearable device adoption.

Cost, Longevity, and Sustainability

Optimized battery performance reduces maintenance calls, replacement cycles, and electronic waste. For industrial or healthcare IoT applications, longer battery life also translates to lower operational costs and higher ROI.

Common Battery Drains in Wearable Devices

Before implementing solutions, it’s important to understand where power is consumed in a typical wearable IoT device.

| Component | Relative Consumption | Notes |

|---|---|---|

| BLE Radio (Idle) | 10–15 mA | BLE is low power, but varies with an interval |

| BLE Radio (Transmit) | 15–30 mA | Higher TX power shortens battery life |

| GPS Module | 20–60 mA | Power-hungry for constant tracking |

| MCU (Active) | 5–15 mA | Depends on clock and workload |

| Sensors (Active) | 1–10 mA | Varies widely by sensor type |

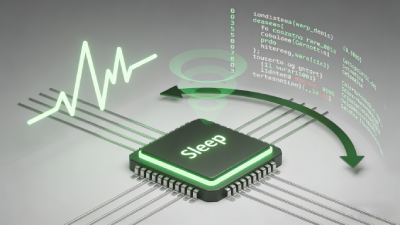

Typical wearable devices spend most of their life in sleep mode (microamps) and only briefly wake for sensing, processing, or transmission. Optimizing duty cycles and sleep behavior significantly influences battery life.

Hardware Components and Power Sink

Communication modules (BLE, LTE/5G), sensors (GPS, accelerometer), and displays are common battery drains. Each must be tuned for efficient, intermittent usage rather than continuous operation.

Hardware-Level Strategies for Low-Power IoT Design

Optimizing at the hardware level lays the foundation for efficient power saving.

Selecting Ultra-Low-Power Microcontrollers

Choose MCUs with multiple power modes (sleep, deep sleep) and low quiescent current (< 1 µA) for idle states. Advanced power regulators (PMICs) also reduce overhead.

Efficient Battery Chemistry

Battery chemistry influences capacity and longevity. For example, lithium-ion (Li-ion) offers high energy density ideal for wearables, while coin cell batteries can last months in low-power BLE applications when advertising infrequently.

Optimized PCB and Power Pathways

Proper PCB layout, short trace routing, and low-leakage materials reduce parasitic power loss. Including shutdown controls for non-critical circuits allows hardware blocks to power down completely when not in use.

Firmware Techniques to Extend Battery Life

Firmware controls the on/off state, sleep cycles, and duty cycles of the entire system — a primary area for IoT power saving.

Duty Cycling and Sleep Modes

Devices should spend most of their time in sleep or deep sleep, waking briefly for essential tasks. This duty cycle model drastically improves energy efficiency, since idle current can be several orders of magnitude lower than active current.

Event-Driven Operation

Instead of periodic polling, use interrupts and event triggers (e.g., motion detected) to minimize unnecessary wake cycles.

Dynamic Voltage and Frequency Scaling

Adjust processor performance based on workload — lowering frequency and voltage during idle or low-demand phases leads to lower energy use.

Connectivity Optimization — Smart Radio Management

Communication modules typically represent the largest power sink in any IoT system.

BLE Advertising and Connection Tuning

Bluetooth Low Energy allows flexible configuration. Increasing the advertising interval and reducing transmit power can extend battery life from months to years in beacon use cases.

Low-Power Wide Area Networks

LPWAN technologies such as NB-IoT, LTE-M, and LoRaWAN are designed for intermittent, low-power communication — ideal for devices that don’t require continuous streaming.

Batching Data and Edge Processing

Reducing transmission frequency by batching data or pre-processing locally conserves power — especially in remote or low-bandwidth environments.

Sensor and Display Optimization

Sensors and displays are often overlooked power consumers.

Motion and Proximity-Based Activation

Activate high-power sensors (e.g., GPS) only when necessary. Low-power motion sensors can act as triggers, conserving energy when the device is idle.

Adaptive Display Brightness

Displays consume significant energy. Using ambient light sensors and adaptive brightness, or turning off the display when inactive, improves wearable battery optimization.

Optimizing UI Behavior

Reducing frame rates and animation workloads also reduces consumption without compromising user experience.

Software, AI, and Predictive Power Management

Advanced software strategies can further extend battery life with predictive control.

Machine Learning for Power Prediction

ML models can forecast device usage patterns and intelligently schedule sleep cycles or connectivity events to maximize battery life.

Firmware Over-The-Air (OTA) Updates

Continuous firmware updates allow devices in the field to receive more efficient power handling code — improving battery performance over time.

Real-Time Power Analytics

Integrating analytics dashboards helps engineers monitor battery trends and adjust operational parameters proactively.

Testing and Validation for Real-World Power Use

Measuring and testing battery behavior under real conditions is essential.

Current Profiling Tools

Accurate measurement tools that capture dynamic currents from microamps to amps help evaluate true power consumption patterns.

Scenario-Based Testing

Simulate sleep-wake patterns, connectivity bursts, and sensor activation to model real deployment behavior.

Future Trends in Energy-Efficient Wearables

Emerging innovations are reshaping IoT power saving.

Energy Harvesting

Technology that captures energy from environmental sources (solar, thermal, motion) can supplement batteries and extend runtime.

Ultra-Low-Power Chipsets

New processor families designed for IoT workloads offer deep sleep modes and sub-milliwatt operation.

FAQs (Frequently Asked Questions)

Q1: How long can a wearable IoT device battery typically last?

Battery life varies by duty cycle and connectivity. With optimized BLE settings, some beacon devices can last 1–3 years on a coin cell battery.

Q2: What’s the biggest power draw in wearable IoT devices?

Wireless communication (BLE, cellular) and high-power sensors (GPS) are typically the largest consumers of energy.

Q3: Does adaptive sampling help battery life?

Yes — adjusting sensor sampling based on activity significantly reduces power use compared with continuous sampling.

Conclusion

Maximizing battery life in wearable IoT devices requires a holistic approach — balancing hardware design, firmware efficiency, connectivity strategy, and testing. With thoughtful wearable battery optimization and IoT power saving practices, developers can deliver long-lasting, efficient, and user-friendly products that stand out in a crowded market.

About Eview

Eview GPS Technology, based in Shenzhen with over 16 years of experience, is a leading provider of Personal Safety Devices and smart tracking solutions. The company designs and manufactures mPERS devices, SOS watches, smart wearables, and home safety hubs for seniors, workers, and families worldwide.

As a trusted OEM & ODM partner, Eview offers full customization—from concept and design to hardware, firmware, and software development. Its integrated ODM solutions cover IoT design, testing, and certification, ensuring performance, compliance, and reliability. With strong engineering expertise, efficient manufacturing, and strict quality control, Eview helps brands accelerate time-to-market and deliver high-quality, user-focused products.