In the fast-growing world of connected safety technology, choosing the right manufacturing partner can decide the fate of your project. A great OEM or ODM partner can transform an idea into a certified, reliable, and scalable product.

A poor choice can lead to delays, budget overruns, and compromised safety. For companies designing smart wearables, sensors, and connected alarms, this guide will help you navigate the process of selecting the ideal IoT OEM manufacturing partner for your next safety device ODM project.

Why OEM/ODM Partnerships Matter

Safety devices have evolved from basic alarms into intelligent connected systems. They protect lone workers, monitor health signals, and transmit real-time alerts. Behind each of these innovations stands a manufacturer who understands both engineering and human risk. That’s what separates a wearable OEM from a generic electronics producer.

According to MarketsandMarkets, the IoT device manufacturing industry is expected to exceed $590 billion by 2025, with industrial and safety wearables among the fastest-growing categories. Companies in this sector need partners capable of handling sensors, connectivity, and compliance simultaneously. Without the right expertise, even a brilliant concept can collapse under the pressure of certification, testing, and scaling.

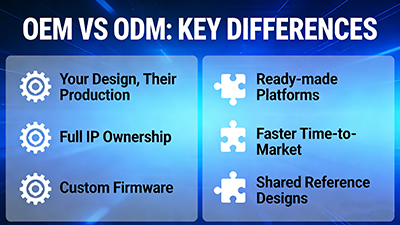

OEM vs ODM: Understanding the Model

In simple terms, an OEM builds according to your design. You own the intellectual property, control the firmware, and manage the roadmap. An ODM, however, provides a ready-made platform, often including hardware schematics, firmware stacks, and pre-tested modules. This approach speeds up time-to-market but may involve shared IP or licensing.

Most IoT safety projects use a hybrid model. The OEM focuses on precise manufacturing and quality control, while the ODM contributes tested reference designs for connectivity and sensors. This balance reduces risk, shortens development, and improves product stability.

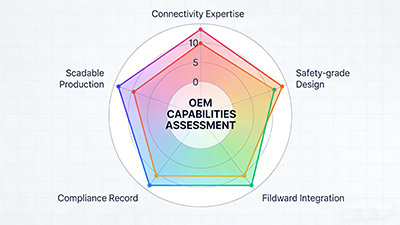

Five Core Capabilities Every OEM Must Have

When evaluating potential partners, focus on competence rather than cost. The following five pillars define a strong IoT OEM manufacturing partner.

| Capability | Why It Matters |

|---|---|

| Connectivity expertise | Experience with NB-IoT, LTE-M, LoRa, or BLE ensures the device stays connected in real-world conditions. |

| Safety-grade design | Rugged, ergonomic, and certified construction keeps users protected. |

| Firmware integration | Built-in support for OTA updates and encryption extends the device’s lifespan. |

| Compliance record | Proven history with FCC, CE, or ATEX speeds certification. |

| Scalable production | Smooth ramp-up from pilot to mass volume avoids costly delays. |

An experienced OEM doesn’t just build hardware—it builds confidence.

Designing for Safety and Human Use

A safety device is more than a circuit board. It must survive dust, drops, and long hours of wear. Good design blends engineering with empathy. Rounded corners prevent injuries. Buttons must be reachable even with gloves. LEDs and buzzers must remain visible in daylight and audible in noise. Battery endurance should last at least one full shift.

A reliable wearable OEM also considers comfort. A device that feels heavy or awkward will be ignored by users. In safety, compliance equals survival. The best manufacturers combine field testing, user feedback, and industrial ergonomics to make devices that workers actually want to wear.

Firmware and Cloud Integration

Hardware keeps people safe, but firmware makes the system intelligent. The right safety device ODM partner will have proven experience with secure over-the-air updates, encrypted communication, and cloud integration. That means compatibility with AWS IoT Core, Azure IoT Hub, or other industrial platforms.

Short sentences keep this point clear. Firmware must be reliable. Data must stay private. Over time, modular code structures help add new sensors or analytics features without major redesigns. That flexibility saves cost and extends product life.

Certification and Compliance: The Hidden Challenge

Certification can be the biggest bottleneck in IoT manufacturing. A strong OEM should plan testing early and guide you through it.

| Certification | Region / Focus | Purpose |

|---|---|---|

| FCC / CE | U.S. & EU | Radio and electromagnetic compliance |

| ATEX / IECEx | Industrial & hazardous sites | Explosion-proof design |

| UL / RoHS | Global | Electrical and environmental safety |

| ISO 13485 | Medical / health wearables | Quality management system |

An OEM with pre-certified modules can shorten development by up to 25 %. This advantage often makes the difference between a timely launch and a missed season.

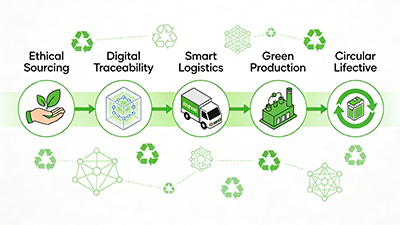

Supply Chain and Sustainability

Today’s buyers value transparency. Knowing where components come from, how workers are treated, and how waste is handled matters more than ever. A responsible OEM should disclose its suppliers, track parts digitally, and plan around component obsolescence.

Sustainable production also reduces risk. Factories with multiple assembly lines can maintain continuity during disruptions. Modern partners use smart logistics, real-time inventory, and ethical sourcing to guarantee supply stability. In a world still facing chip shortages, visibility is power.

After-Sales and Lifecycle Support

A strong partnership doesn’t end with the shipment. It continues throughout the product’s lifecycle. OEMs that offer robust after-sales support can repair faults faster, deliver firmware fixes remotely, and analyze failure data to prevent recurrence.

Prompt response time builds trust. Long sentences aside, it’s simple: service defines loyalty. A manufacturer who helps you improve the product after launch is worth more than one who just ships on time.

Support defines long-term success. Look for:

-

Root-cause analysis for returns.

-

Firmware patch cycles within weeks, not months.

-

Local RMA centers to shorten turnaround.

-

Regular production audits for consistency.

Short sentences deliver the message clearly: good service reduces lifetime cost.

Insights from the Community

Across engineering forums and founder discussions, the same advice repeats itself. Always request production samples before mass orders. Clarify IP ownership, especially when working with ODMs that use shared designs. Watch for hidden costs such as tooling, test setup, and compliance documentation. And never skip pilot runs—real conditions reveal real weaknesses.

Professionals emphasize one last rule: communication is everything. The best OEMs share problems early, not after deadlines pass. Openness saves projects.

Before You Sign the Contract

Review the essentials carefully. Confirm the NDA and ownership clauses. Make sure all milestones—from prototype to certification—are written down. Check warranty coverage, response times, and quality metrics. A transparent cost model avoids confusion later.

One long, final thought: a detailed agreement transforms uncertainty into partnership. When both sides understand expectations, collaboration becomes smoother, and risk becomes manageable.

-

NDA signed and reviewed.

-

IP and tooling ownership is clearly stated.

-

Defined delivery and certification milestones.

-

Warranty terms in writing.

-

Transparent pricing model.

-

Exit and revision clauses.

Longer sentence for clarity: a detailed contract keeps both parties accountable from prototype through production.

Conclusion: Building More Than Hardware

Selecting the right IoT OEM manufacturing or safety device ODM partner is about more than production capacity. It’s about finding a collaborator who shares your standards for reliability and safety. A skilled wearable OEM accelerates certification, maintains quality, and scales production without compromise.

In the IoT safety world, trust is the ultimate technology. Choose a partner who values it as much as you do.

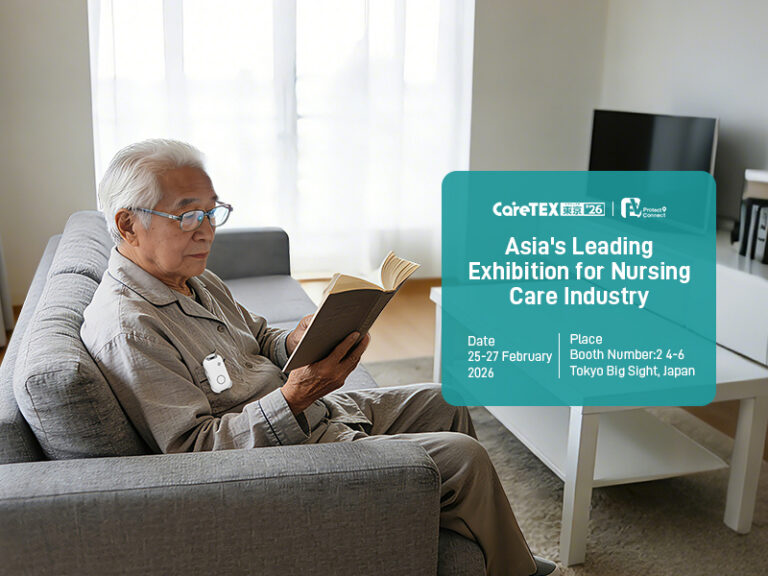

About Eview

Eview GPS Technology is a leading provider of smart safety and tracking solutions with over 16 years of experience. Based in Shenzhen, Eview designs and manufactures mPERS devices, SOS watches, smart wearables, and home safety hubs serving seniors, workers, and families worldwide.

As a trusted OEM & ODM partner, Eview delivers complete customization services—from concept and industrial design to hardware, firmware, and software development. With strong engineering expertise and flexible cooperation models, we turn innovative ideas into reliable, market-ready products that reflect each brand’s unique identity.

Eview’s ODM solutions integrate product design, IoT development, testing, and certification, ensuring performance, compliance, and user satisfaction. Our efficient manufacturing and strict quality control systems guarantee consistent excellence.

Partnering with Eview means gaining a dedicated team that provides end-to-end innovation, quality assurance, and tailored support, helping global clients accelerate time-to-market and achieve long-term success.

FAQ — About IoT OEM Manufacturing and Safety Device ODM

Q1. What is IoT OEM manufacturing?

It’s the process where a specialized company produces IoT hardware under your brand, handling assembly, testing, and certification.

Q2. How does a wearable OEM differ from a safety device ODM?

A wearable OEM builds to your blueprint. A safety device ODM co-designs and integrates firmware, offering faster launch times.

Q3. How long does a typical IoT OEM project take?

On average, six to nine months from prototype to mass production.

Q4. How can companies protect intellectual property?

Use NDAs, clarify ownership of design files, and maintain firmware source-code access.

Q5. Which certifications matter most for safety devices?

FCC, CE, ATEX, and ISO 13485—depending on the target market and environment.