Understanding the supply chain and production capacity is very important for you as a GPS SOS watch buyer. These things affect your buying choices. For example, a factory larger than 1,000 m² usually has automated assembly lines. This means they can produce items at a steady rate. Also, a production lead time of 14 days or less is key for launching products on time. You need to think about these factors to make sure products are available and meet market needs well.

Key Takeaways

- Know the parts of the supply chain like making products, suppliers, shipping, and distribution. This helps you make smart buying choices.

- Keep an eye on how much can be made and how long it takes. This ensures products launch on time and keeps customers happy.

- Create strong connections with trustworthy suppliers. This helps you get good materials and improves delivery.

- Spot possible problems in the supply chain, like delays and quality issues. This helps you come up with good plans to fix them.

- Use technology and clear communication to make your supply chain work better and respond faster.

Supply Chain Overview

Key Components

When you think about the supply chain for GPS SOS watches, there are several important parts. Knowing these parts helps you make smart buying choices. Here are the main parts:

- Manufacturing: This is about making GPS SOS watches. It includes putting together hardware and software. A good manufacturer, like Eview, makes sure production is high quality and efficient.

- Suppliers: These are the companies that give raw materials and parts needed for making watches. Good relationships with suppliers can help you get better prices and more availability.

- Logistics: This means moving materials and finished products. Good logistics make sure things are delivered on time, which is important for keeping enough stock.

- Distribution: This is how the final products get to customers. Good distribution plans can help you reach more people and keep customers happy.

- Technology: New technologies, like IoT and cloud computing, are important for tracking supply chain processes. They help improve efficiency and allow real-time data access.

Disruption Impacts

Supply chain problems can greatly affect how available and costly GPS SOS watches are. You need to know about these issues to handle challenges well. Here are some key points to think about:

- Availability: Problems can cause delays in making and shipping products. For example, political issues may slow down material flow, leading to stock shortages. This can mean lost sales and unhappy customers.

- Cost: Higher shipping costs and material shortages can raise prices. If a supplier has issues, they might charge you more, which can hurt your profits.

- Market Share: Problems can change how companies compete. Brands that manage their supply chains well can gain market share from those that do not. The table below shows how supply chain issues can affect market share:

| Category | Details |

|---|---|

| Strengths | End-to-end module-to-cloud offering. |

| Weaknesses | Dependence on cyclical industrial sectors. |

| Opportunities | 5G RedCap enables affordable high-speed tracking. |

| Threats | Geopolitical supply-chain disruptions. |

- Efficiency: Problems can cause inefficiencies in operations. You may need to change your plans to lessen these effects, like finding new suppliers or using technology to improve visibility.

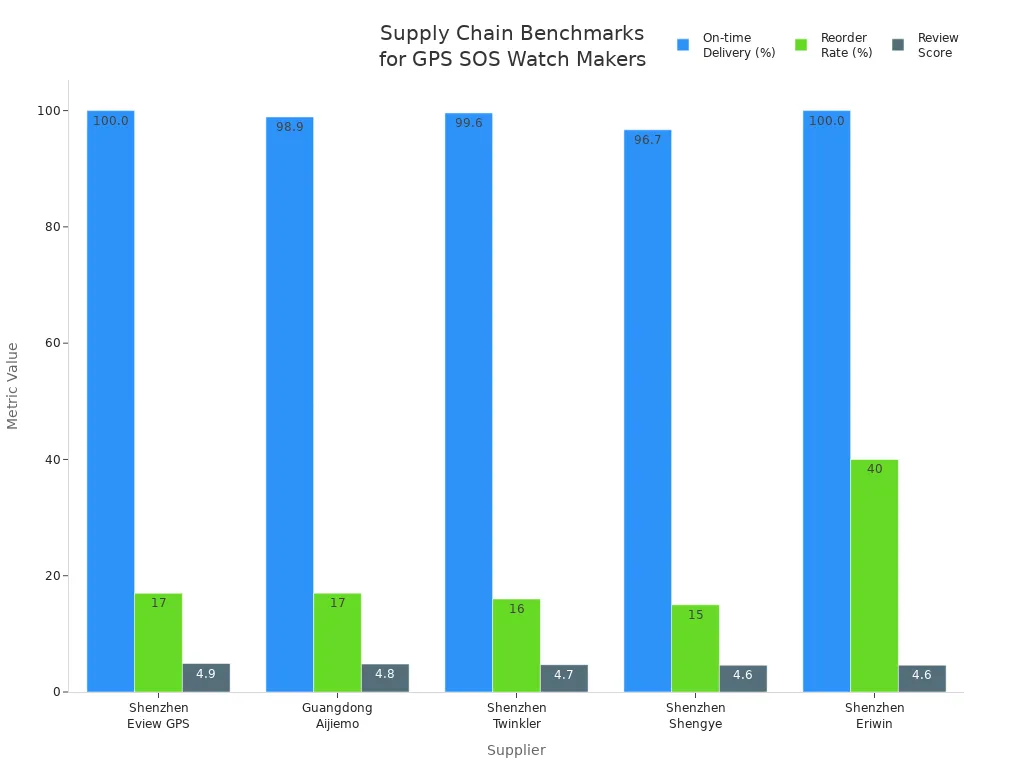

To show how well top suppliers perform in the GPS SOS watch market, look at this table:

| Supplier | Review Score | Response Time | On-time Delivery | Annual Revenue (Est.) | Reorder Rate |

|---|---|---|---|---|---|

| Shenzhen Eview GPS Technology | 4.9/5.0 | ≤5h | 100.0% | $460,000+ | 17% |

| Guangdong Aijiemo Electronic Industry Co., Ltd. | 4.8/5.0 | ≤4h | 98.9% | $63,000+ | 17% |

| Shenzhen Twinkler Technology Co., Ltd. | 4.7/5.0 | ≤4h | 99.6% | $910,000+ | 16% |

| Shenzhen Shengye Technology Co., Ltd. | 4.6/5.0 | ≤5h | 96.7% | $690,000+ | 15% |

| Shenzhen Eriwin Technology Limited | 4.6/5.0 | ≤5h | 100.0% | $150,000+ | 40% |

By knowing these parts and possible problems, you can make smart choices that strengthen your supply chain and help you successfully buy GPS SOS watches.

Production Capacity Factors

OEM Production Capacity

In OEM projects, production capacity means how well a manufacturer can make GPS SOS watches. This includes both small and large production runs. Knowing this capacity is important for launching products on time and staying ahead of competitors.

To check and report OEM production capacity, think about these points:

| Aspect | Details |

|---|---|

| Production Capacity | Ability to handle both small batch and large-scale production. |

| Lead Times | Check lead times to meet deadlines for product launches. |

| Customization Capabilities | Focus on customization to meet unique brand needs and quality control. |

Influencing Factors

Many factors can affect the production capacity of GPS SOS watches. By knowing these factors, you can make better choices that improve your supply chain.

- Technology: New manufacturing technology helps increase production capacity. For example, better battery management systems improve battery life and add solar charging. This is great for outdoor users who need long-lasting devices. Also, adding biometric sensors like SpO2 and ECG monitoring attracts health-conscious buyers.

- Materials: The quality and availability of materials impact production capacity. Good suppliers make sure you get high-quality parts on time. Delays in material delivery can slow down your production.

- Workforce: A skilled workforce is key for high production capacity. Training programs can help reduce mistakes in production. But if workers are absent, it can cause short-term slowdowns.

- Maintenance Practices: Good maintenance plans are important to reduce machine downtime. Old maintenance methods can lead to more downtime, which disrupts production. Using proactive maintenance schedules can help avoid these problems.

- Communication: Clear communication in your production team is very important. Poor communication can cause delays and problems. Setting up better communication channels can improve teamwork and boost production capacity.

- Bottlenecks: Finding common bottlenecks in production is important for improving capacity. Here are some common bottlenecks you might see:

| Bottleneck Type | Description |

|---|---|

| Absenteeism | Absent employees can create short-term bottlenecks when their position cannot be filled. |

| Training | Inconsistent training across jobs can lead to bottlenecks if new operators require additional resources. |

| Manual Production Monitoring | Human errors in manual monitoring can cause delays and outdated data, impacting production efficiency. |

| Reactive or Preventive Maintenance | Outdated maintenance strategies can increase machine downtime, creating bottlenecks. |

| Manual Change Orders | Slow movement of manual change orders can create bottlenecks in the production process. |

| Communication | Poor communication methods can lead to delays and inefficiencies in manufacturing. |

| Processes | Task-driven constraints can occur when production requests exceed machine capacity. |

| Resources | Limited labor hours for specialized skills can create resource bottlenecks. |

| Technology | Fragmented software systems can lead to technology bottlenecks, interrupting workflow. |

By understanding these factors, you can improve your production capacity and make sure your GPS SOS watches meet market needs effectively.

Strategic Sourcing and Partnerships

Reliable Suppliers

Choosing reliable suppliers is very important for your success in the GPS SOS watch market. A good supplier makes sure you get high-quality parts on time. This reliability affects the quality and delivery of your products. Here are some key points to check supplier reliability:

| Criteria | Description |

|---|---|

| Quality Assurance | Parts go through strict checks to ensure quality and performance. |

| Component Sourcing | High-quality parts come from trusted suppliers to use the latest technology. |

| Adherence to Standards | Manufacturing follows strict quality rules to meet high performance standards. |

By focusing on these points, you can create a strong base for your supply chain.

Partnership Benefits

Creating partnerships with suppliers can lead to better production results. Working with reliable partners, like Eview, helps you increase production and meet market needs. Here are some benefits of strategic partnerships:

- Supply Chain Modernization: Digital changes improve transparency, speed, and strength, which are key for increasing production.

- Competitive Pricing: Smart sourcing of advanced parts helps you meet growing demand while keeping products available.

- Quality Control: Strict quality checks are done from making to packaging, ensuring high standards.

These partnerships not only boost your production ability but also encourage new ideas. By working closely with suppliers, you can access new technologies and insights that can improve your products.

Risk Management in Supply Chain

Risk Identification

Finding risks in the supply chain for GPS SOS watches is very important. It helps keep everything running smoothly. Here are some common risks to know about:

- Cargo Theft: Thieves often target shipments. They use GPS jammers to turn off tracking devices. This makes it easier for them to steal trucks and containers.

- Supply Chain Disruptions: Events like natural disasters, political problems, or pandemics can stop production and delay shipments.

- Supplier Reliability: Relying on just one supplier can be risky. If that supplier has money problems or other issues, it can hurt you.

- Quality Control Issues: Using bad quality materials can cause product failures. This can hurt your brand’s reputation and customer trust.

Mitigation Strategies

To manage these risks well, you can use several strategies:

- Document Risks: Find and write down possible risks. This helps create a strong risk management plan.

- Utilize Digital Tools: Use digital tools to watch for risks. They can give you real-time data and alerts.

- Regular Reviews: Check your supply chain processes often. This helps find new risks and check on old ones.

- Diversify Suppliers: Don’t rely on just one supplier. Get parts from different sources. This lessens the impact if one supplier fails.

- Maintain Buffer Stock: Keep extra stock of important parts. This helps keep production going during supply problems.

- Clear Communication: Set up clear ways to talk with suppliers. This helps you respond quickly to issues.

- Training and Culture: Build a culture that understands risks. Encourage openness and quick responses. Train employees on risk management.

- Contracts with Risk Clauses: Write contracts that include risk-sharing clauses. This protects you if there are disruptions.

By finding risks early and using these strategies, you can make your supply chain stronger. This helps ensure the successful delivery of GPS SOS watches.

In conclusion, knowing about supply chain and production capacity is very important for you as a GPS SOS watch buyer. Think about these main points:

- A supplier’s ability to produce affects how quickly products arrive, which impacts how happy customers are.

- Strong production skills help keep enough stock when demand goes up, making customers happy.

- The quality of materials in your products greatly affects how satisfied users are.

By paying attention to these factors, you can make smart buying choices that improve your market position and keep customers loyal.

FAQ

What features should I look for in a GPS SOS watch?

Look for features like GPS tracking, fall detection, SOS alerts, and long battery life. Make sure the watch is waterproof and easy to use.

How can I ensure timely delivery of my order?

To get your order on time, pick suppliers known for on-time delivery. Keep in touch with your suppliers and check production schedules often.

What is the typical lead time for GPS SOS watches?

The usual lead time for GPS SOS watches is 2 to 4 weeks after you approve the sample or confirm payment. However, this can change based on order size and customization needs.

Can I customize the GPS SOS watch for my brand?

Yes, you can customize GPS SOS watches using OEM services. Custom options include branding, firmware changes, and packaging design to match your brand.

How do I handle supply chain disruptions?

To manage supply chain problems, use different suppliers, keep extra stock, and have risk management plans. Regularly check your supply chain processes to find possible weak spots.